Physical properties of materials

- Hardness is the mechanical resistance that a body offers to the penetration of another, harder body.

- Density, formula symbol: ρ (Greek: rho), is a physical property of a material. It is defined by the ratio of the mass m of a body to its volume V: r = m/V

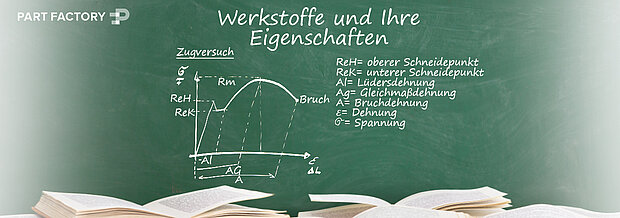

- Strength is a material property that describes the resistance of a material to failure. Depending on the material and the load, failure can be, for example, brittle fracture or plastic deformation.

- Elasticity is the property of a material to offer mechanical resistance to the applied force and to resume its original shape after unloading. Contrast: plasticity.

- Plasticity is the melting of a substance or material under the action of such high stresses that elastic recovery is no longer possible.

Technological properties of materials

- Thermal conductivity is the ability of a solid, liquid or gas to transport thermal energy in the form of heat.

- Castability is the ability of a material to assume a given shape by casting in molds.

- Formability is the property of a material to be permanently formed by external stress.

- Machinability describes the properties of a material for machining.

The shape of workpieces is changed by machining (formerly metal cutting), such as turning, milling and drilling. The suitability of a material for machining is referred to as its machinability. Materials that can be machined well exhibit smooth surfaces after machining and produce chips that do not interfere with the manufacturing process. Depending on the manufacturing process, a certain material property can have a favorable or unfavorable effect on machining.