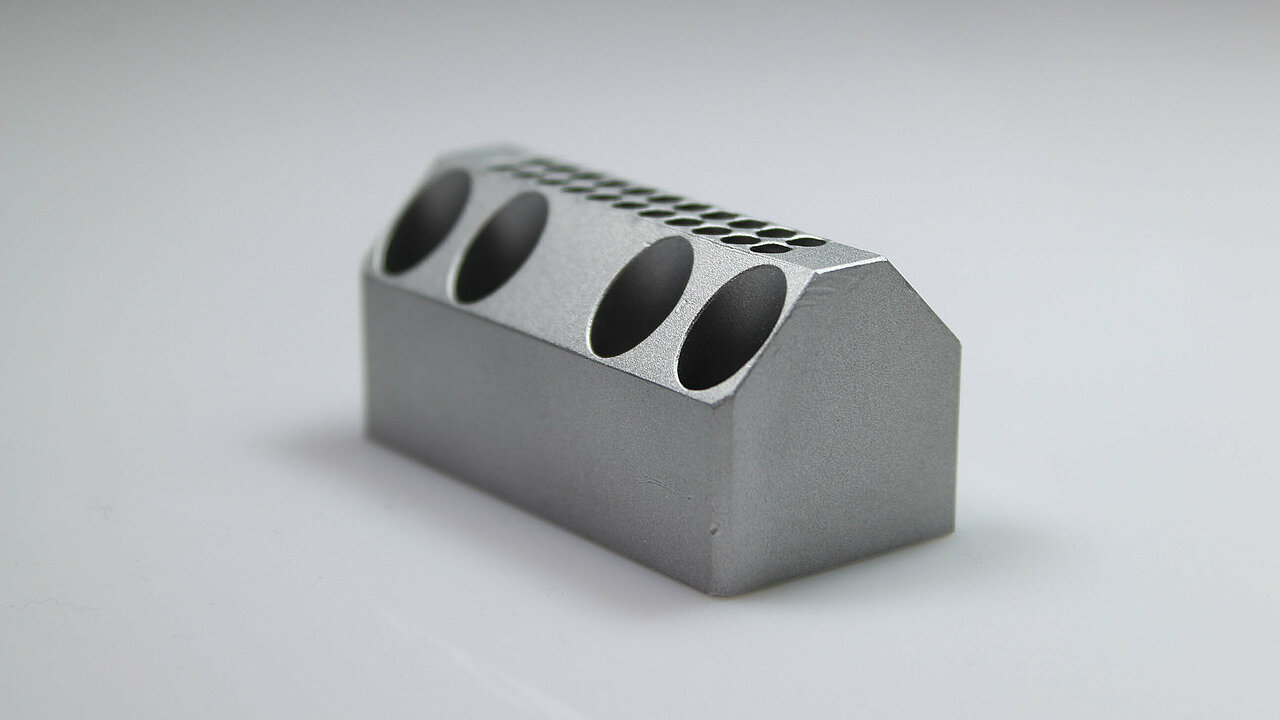

In addition to quickly available, low-priced offers with short delivery times, we at PART FACTORY want to provide you with very good quality

above all.

We attach great importance to the fact that our customers receive the parts that reliably fulfill their function. We outsource the production of your orders to our PART FACTORY producers, with some of whom we have long-standing cooperations.

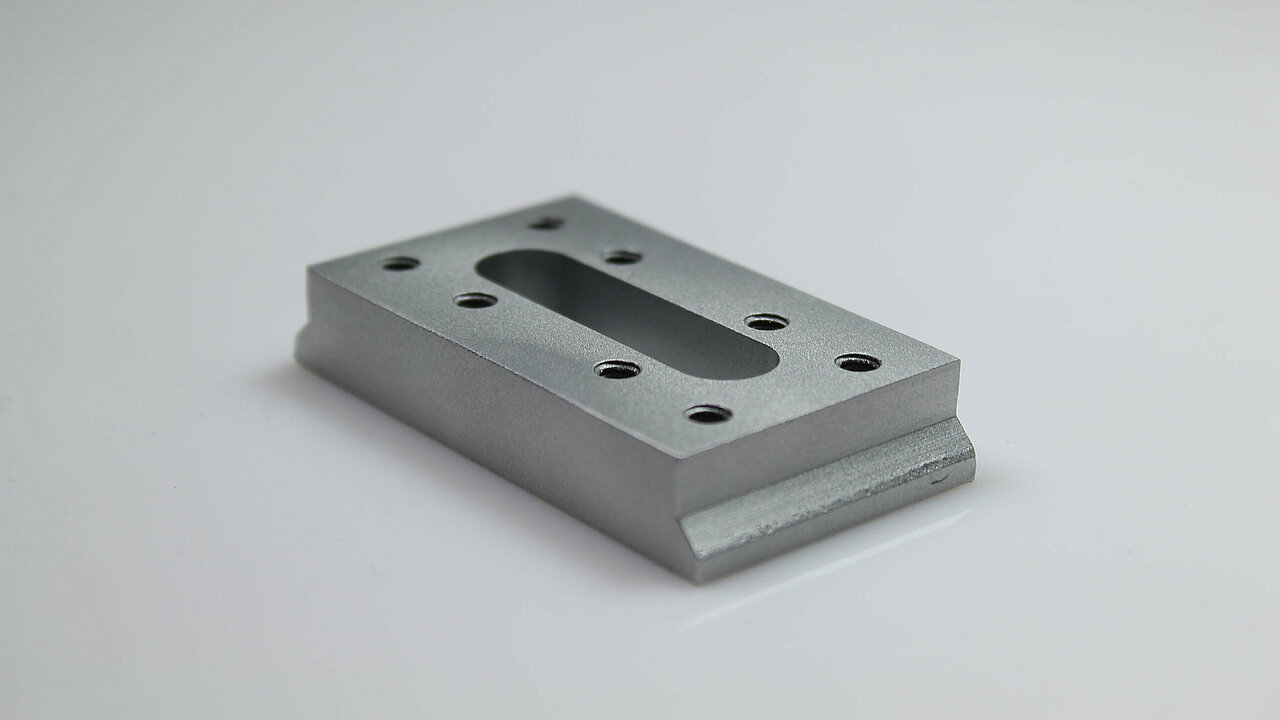

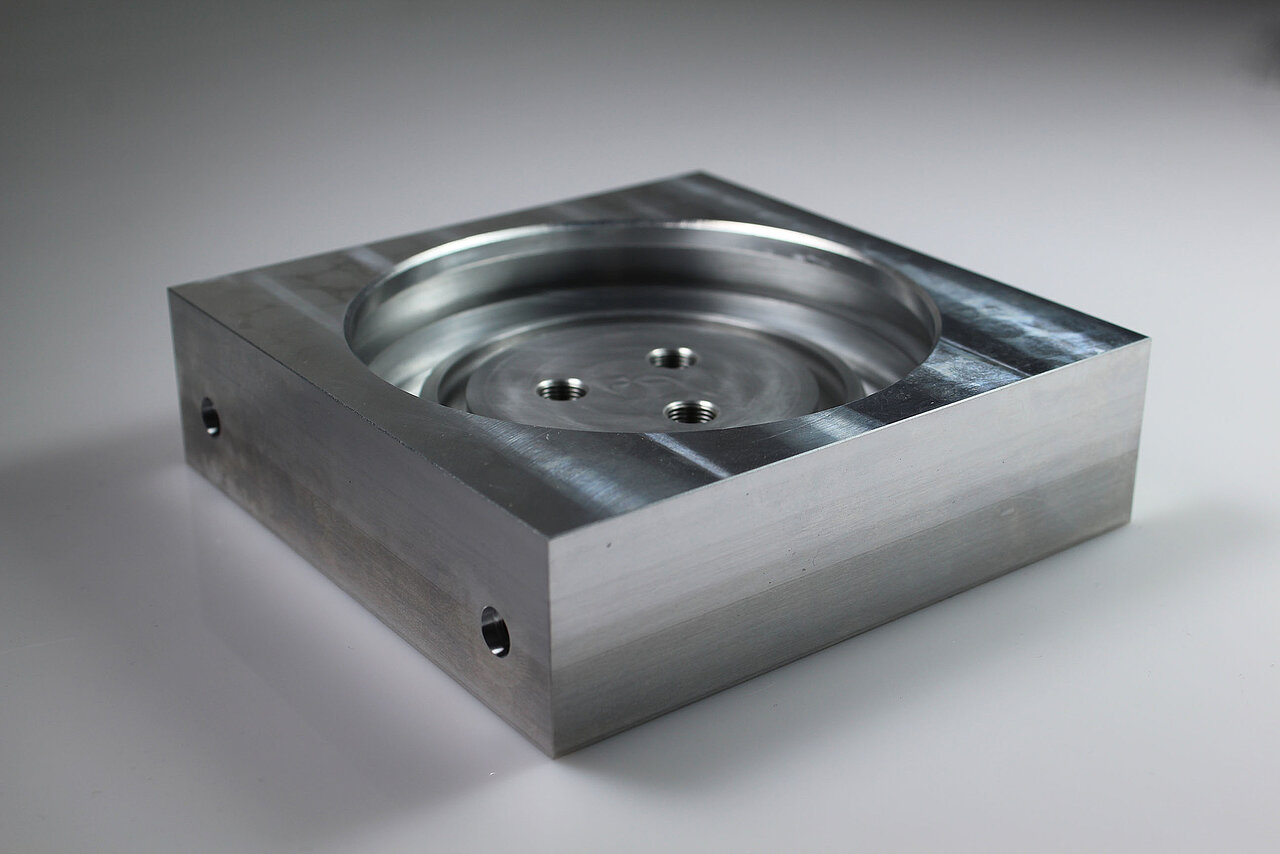

The use of different machines or processing methods can lead to optical differences in parts, but these do not affect the function in any way. Even with repeat orders, small deviations in part optics may occur if your order is manufactured by a different producer than the first time.

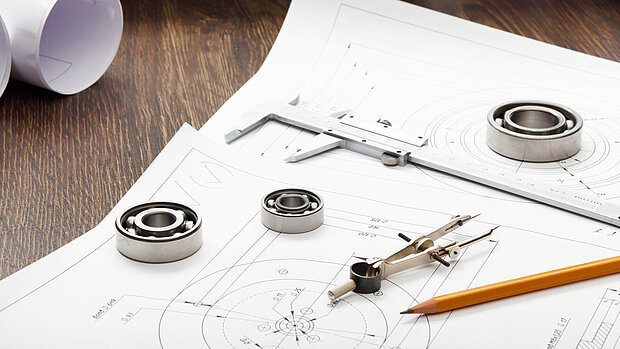

Tips for your manufacturing inquiry

- Specify the material with exact specification

- Provide information on the surface finish (e.g. roughness)

- Give details of the surface treatment (e.g. anodizing)

- Note any special requirements on the drawing (e.g. visible part)

- Indicate if the production is to be carried out analogously to a previous order

Each order is carefully checked both at our producer and in the PART FACTORY and sent to you together with the other orders.

Of course, we take your manufacturing wishes into account, discuss them in advance and check the compliance with the part requirements before we deliver to you. If, for example, you need a visible part with a special surface quality requirement, simply note this on the PDF production drawing and we will be happy to take care of the corresponding production.

Our experienced staff will be happy to provide you with all technical production details without obligation and will realize your desired part - that's good service.

Missing or inaccurate information in the production drawing

The appearance of CNC machined parts depends on many factors. Some of them are rooted in the manufacturing process and are difficult to influence. However, you can use other influencing variables specifically to adapt the parts to your optical requirements:

Quite fundamentally, this is possible, for example, with the material specification. If you specify the material in general terms, e.g. simply "steel", the manufacturer can choose from various alloys which differ both visually and in terms of their machining properties. Therefore, always specify the exact material designation so that a consistent appearance can be achieved. The same applies when specifying the surface roughness and the surface treatment.

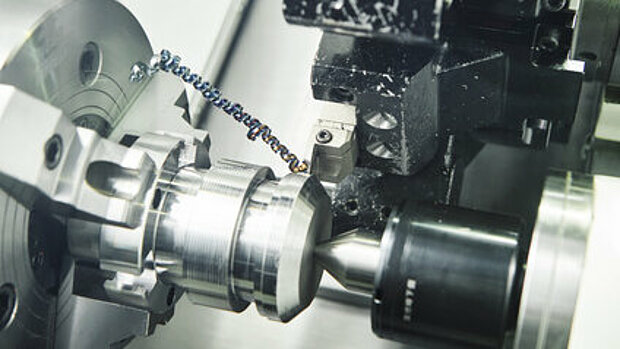

Influences of part manufacturing

The actual production of the part is largely responsible for the later optics.

The process used, the tool and feed rate, but also the cooling of the component have an influence on the later optics. Different processing methods by changing machine operators are also reflected in this way.

Will your part later be used as a visible part, or do you need a polished or particularly smooth surface? Give us these component properties in addition to the roughness specification.

We will take care of the corresponding production!