Adhesion, means the adherence of molecules of solid or liquid substances to each other in the area of interfaces.

When two surfaces meet under the influence of high temperatures, they can weld together. Such welds are also called pressure welds because they occur under the high pressure of machining.

Such pressure welds shear off in the course of further stressing. What remains are crater-like formations (micro-crumbling) on the tool surface. This effect can occur on the rake and flank surfaces.

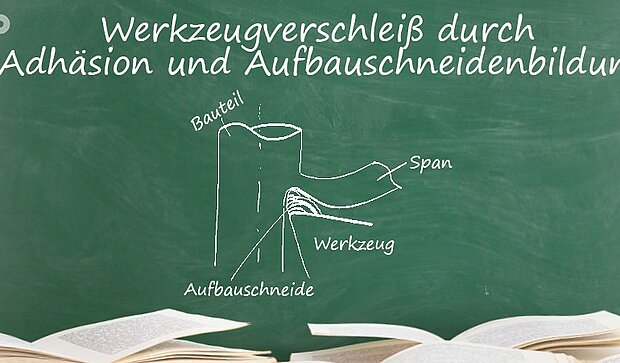

Highly consolidated layers can build up on the rake face and form a "new" tool cutting edge, since the actual cutting edge of the tool is no longer in contact with the chip at all. These are called built-up cutting edges. When they can no longer withstand the cutting load, they shear off at the flank and form anew. This leads to flank wear and poor surface finishes.