Many companies create a so-called prototype before a single-item or series production.

The aim is to ensure that the final product meets the desired requirements.

Therefore, companies like to invest in the development of a prototype so that the development of the final product can move forward.

If companies notice through the prototypes developed,

that the final product does not meet the requirements, the company has saved money.

After all, no serial production of this product has started. Is that the only advantage a prototype has to offer?

And what exactly is behind the term "prototype"?

The word "prototype" is composed of the Greek word "protos" and "typos". "Protos" means "first" and "typos" means "archetype". A prototype is the first realised design of a product.

It is created before series production and serves to compensate for ambiguities in relation to the finished end product.

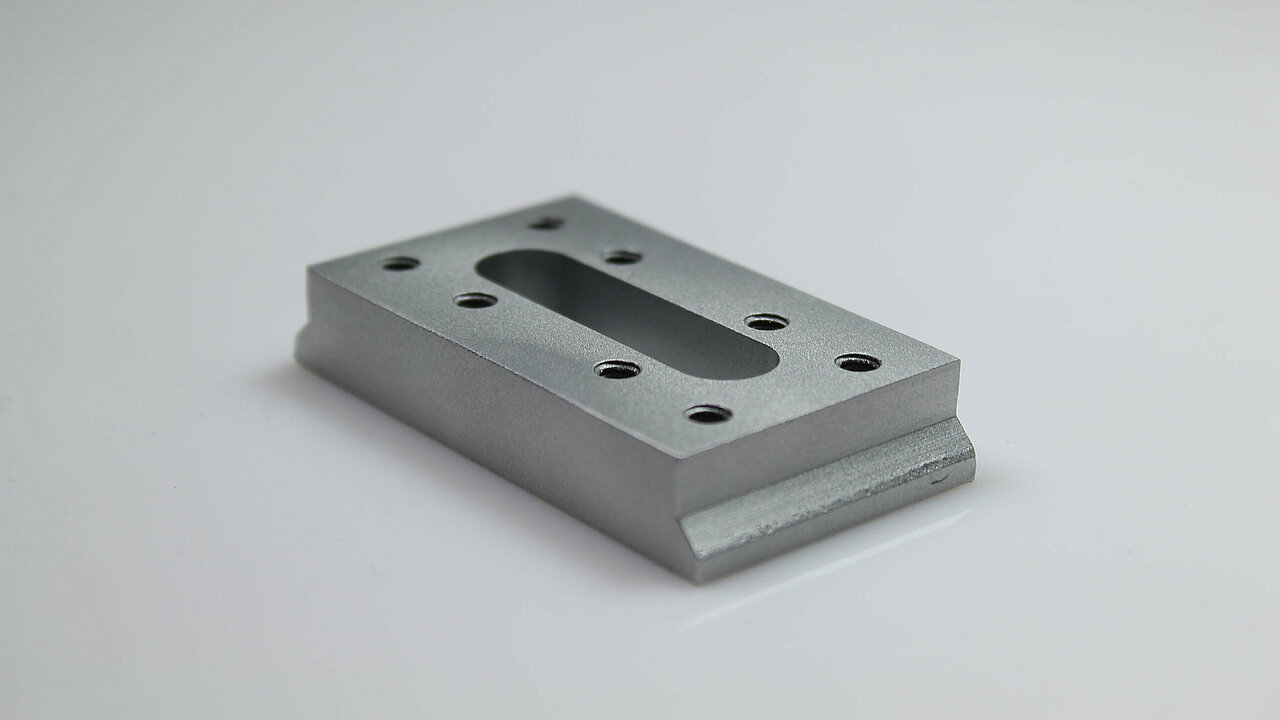

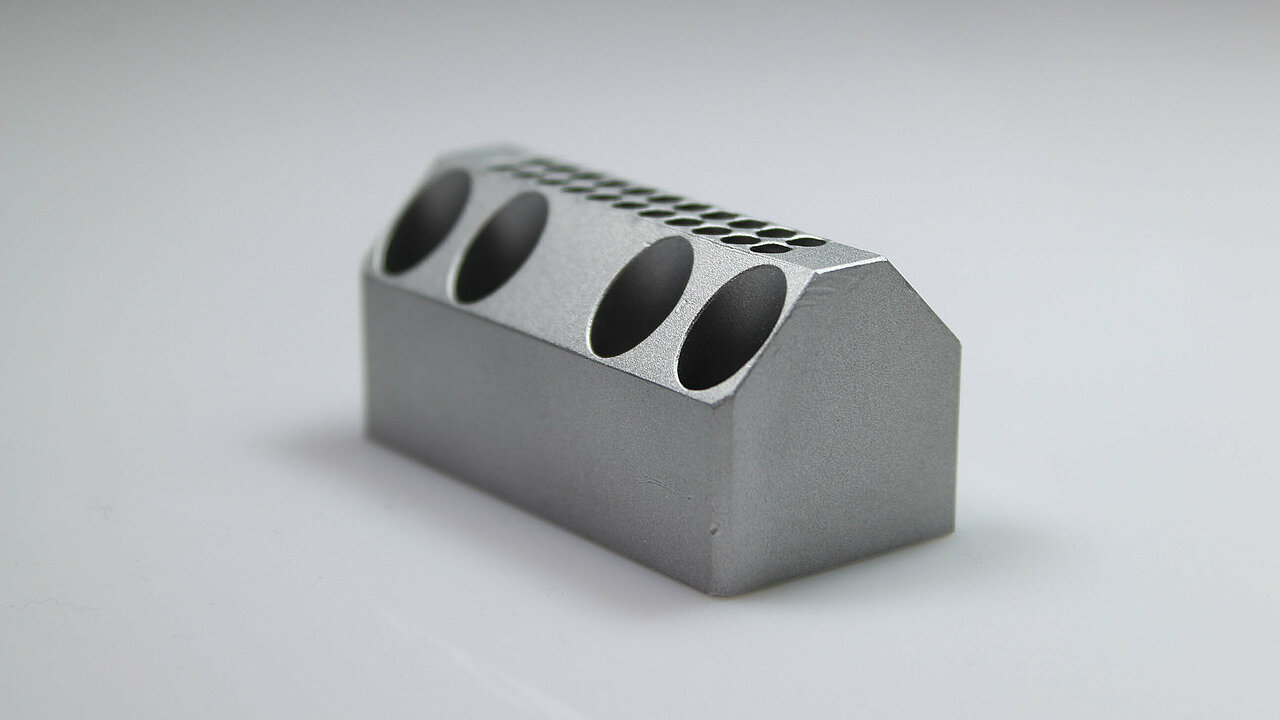

The aim is to check the possible realisation of the functions and appearance of the final product. A distinction is made between different types of prototypes that have to meet different requirements. The design prototype, for example, serves to test aesthetic or ergonomic features. The geometric prototype, on the other hand, is dimensionally accurate in order to check assembly and carry out usage tests. The functional prototype has functional properties of the final product.

The production should be as fast and inexpensive as possible. This way, a lot of money is not spent unnecessarily when changes have to be made. In general, prototypes cost more in one-off production than the later series product.

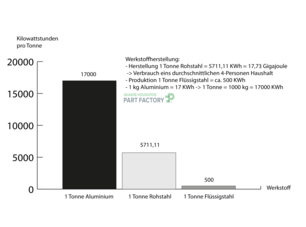

Materials such as steel, plastic, aluminium, brass or titanium can be used. Manufacturing can be cheaper and easier in some cases when additive manufacturing, such as rapid prototyping, is used. When a prototype is made, it is possible that significant defects in function will be found. The final product would then not be fit for purpose. In this case, changes have to be made to the design and thus to the final product. Tests must then be carried out again to obtain feedback on the (improved) function. Performing several tests by modifying the component can become very time-consuming. But the production and testing of prototypes can help to find errors before series production. If series production were to start and all the elements produced were faulty, the costs could be extremely high. An example of this can be found in the automotive industry. If a component has not been tested with the help of a prototype and a faulty series production starts, it can lead to a costly recall of the entire car series.

Manufacturing a prototype can be time-consuming and costly. Therefore, it is usually a good alternative to outsource the manufacturing and procure using contract manufacturing. Many contract manufacturing companies specialise in the production of small series and prototypes, as they often receive enquiries with small quantities or of prototypes. One of the purposes of the prototype is to check the material for the final product. In the process, however, it may become apparent that the material is not the right one, so that the surplus material now sits uselessly in the company. Here, too, contract manufacturing companies can act better, because they are more likely to know how much material is needed for a small number of pieces, such as a prototype. Contract manufacturers can also use surplus material for other requests.

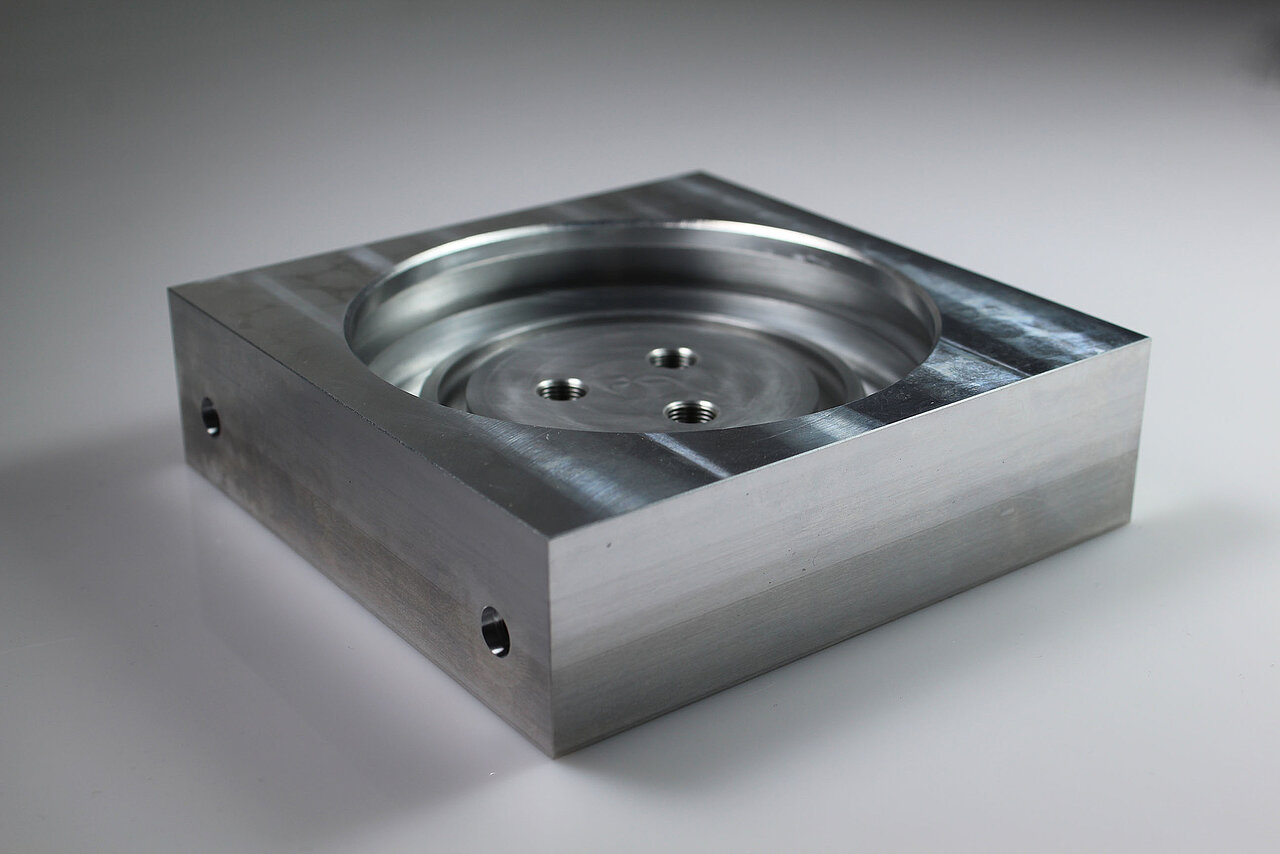

PART FACTORY produces turned and milled parts and focuses on individual and series production, but also on prototypes.

The producers in PART FACTORY's tested network increasingly manufacture small series and prototypes.

Prototypes are designs of end products that are upstream of series production. The production can be extremely time-consuming and costly. To reduce this, the client can outsource the production of the prototypes. This way, the production is done by others. Prototyping is and remains an important step in product development. However, the higher costs save much more costly mistakes in series production.

Try our service!

Convince yourself of our uncomplicated service and make a production enquiry.

You will be surprised how little effort is required.

You can look forward to a high-quality prototype or a corresponding small series that fully corresponds to your production drawing on the desired delivery date. Give it a try - it's worth it!

![[Translate to English:] PART FACTORY_Prototyp [Translate to English:] PART FACTORY_Prototyp](/fileadmin/_processed_/9/f/csm_PART_FACTORY_Prototyp_a5ead7c4ad.jpg)

![[Translate to English:] PART FACTORY_Frästeil_12 [Translate to English:] PART FACTORY_Frästeil_12](/fileadmin/_processed_/5/2/csm_PARTFACTORY_Fraesteil_10_09fdd70534.jpg)

![[Translate to English:] PART FACTORY_Drehteil_2 [Translate to English:] PART FACTORY_Drehteil_2](/fileadmin/_processed_/f/a/csm_PART_FACTORY_Drehteil_1_c69ca595c6.jpg)

![[Translate to English:] PART FACTORY_Prototyp_Lösung [Translate to English:] PART FACTORY_Prototyp_Lösung](/fileadmin/_processed_/0/6/csm_PART_FACTORY_Prototyp_Loesung_b4384f4c64.jpg)

![[Translate to English:] PART FACTORY - Kontaktaufnahme [Translate to English:] PART FACTORY - Kontaktaufnahme](/fileadmin/_processed_/2/4/csm_woman-2773007__340_590260e0fe.jpg)