Properties of Case-hardened steel

Case-hardening steels are structural steels that are suitable for case-hardening.

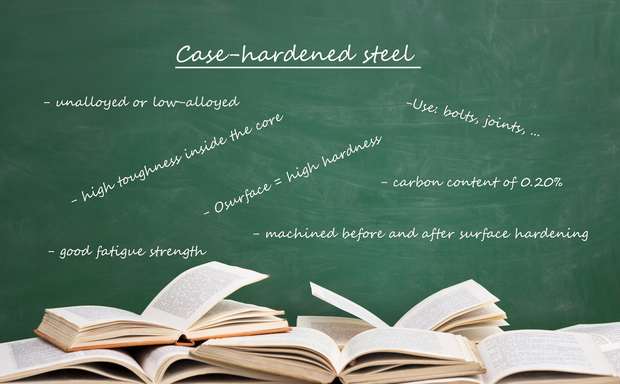

Case-hardening steels can be unalloyed or low-alloyed steels, with a maximum carbon content of 0.20% for both.

The case hardening process gives the steel a high toughness inside the core. The surface also has a high hardness.

Furthermore, case-hardening steels have a high resistance to wear, bending and impact stress.

They are also no longer weldable after case hardening, but have good fatigue strength. The fatigue strength is the load limit of a material.

If this is high, then the material can withstand a large dynamic load, which is generated by vibrations, for example.

Case-hardening steels are produced using the process of case-hardening. This is divided into three steps. Carburisation, hardening and tempering. During carburisation, carbon is added to the material.

To achieve this, the material is placed in a carbon-containing medium and heated to between 880°C and 1050°C. The carbon diffuses through the high temperatures. The carbon diffuses into the surface layer due to the high temperatures, so that the carbon content increases to 0.8%.

This is followed by hardening and quenching. Here the steel is strongly heated and then rapidly cooled. In the third and final step, tempering, heating takes place at lower temperatures than in hardening.

Case hardening is used to obtain a hard surface layer and a tough core.

This makes case-hardening steel wear-resistant. The processing of the material can be divided into two areas. Case hardening steels can be machined before and after surface hardening. Before surface hardening, machining (milling, turning or drilling) and non-cutting machining can take place. After surface hardening, machining steps such as grinding,

eroding or polishing take place.

Do you want to have a milled or turned part made from a case-hardened steel?

Or are you interested in having your desired component milled or drilled with the help of contract manufacturing?

Submit your enquiry quickly and easily and we will get back to you with a quote in line with the market.

We look forward to hearing from you.