The basic material for iron casting and steel casting is an iron-carbon alloy.

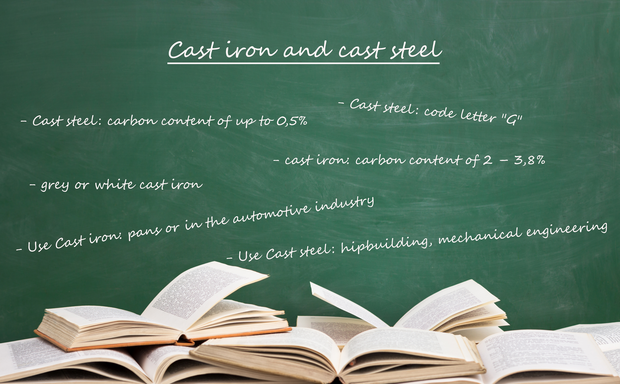

Cast steel is liquid steel cast in a mould. The code letter "G" is placed before the short name,

which is a sequence of numbers and letters. Iron casting is iron in the form of "cast iron" with a density of 7.2 g/cm3.

A distinction is made here between grey and white cast iron.

In grey cast iron, graphite forms in the structure differently from white cast iron, where cementite forms.

Properties of iron casting and steel casting

The properties of cast steel include good castability and good mechanical properties.

Mechanical properties are characteristics of a material such as strength, hardness or elasticity.

Cast steel has a pronounced thermal and chemical resistance, as well as high toughness and strength.

The strength can be adjusted by heat treatment. Cast steel has a melting point of 1600°C,

which is higher than that of cast iron at 1150°C. Due to its low carbon content of up to 0.5%,

cast steel is easier to forge than cast iron, which has a high carbon content of 2 - 3.8%.

The carbon content makes for a strong material. This property is advantageous for many uses,

but affects the above-mentioned forgeability of the material. Silicon increases the castability of iron castings,

which is also good. Silicon causes lamellae to form and the carbon is not bonded to the iron.

It has a high corrosion resistance and stores heat well. In addition to these properties, cast iron is more durable.

The casting materials are melted in electric furnaces, such as an induction furnace. However, the energy required for melting is higher for cast steel than for cast iron. The energy required for melting (also called heat of fusion) is necessary to change a solid substance into a liquid state of aggregation. For this purpose, binding forces in molecules are overcome. Due to the brittle and, especially in the case of cast steel, coarse-grained material, post-treatment of the material is often necessary. Cast iron is hard and brittle and is used in workshop ovens, pans or in the automotive industry. Cast steel, on the other hand, is used in shipbuilding, mechanical engineering or plant construction.