What is behind the energy crisis?

There have been various problems in connection with Nord Stream 1, from which Russian gas is piped to Germany. Firstly, in June 2022, Russia reduced the gas supply to 40% and secondly, on July 11, 2022, Nord Stream 1 was temporarily stopped due to maintenance work. Then, at the end of August, the gas supply from Russia to Germany was completely interrupted.

These events and the coming winter cranked up the energy crisis

and the price increases.

Further, wholesale electricity prices have tripled since mid-June 2022.

The energy crisis is a new challenge for contract manufacturing.

One is confronted with incalculable energy costs, which, for example, makes the calculation of offers immensely difficult.

As a result of the energy crisis, prices for gas, oil and electricity are rising, and with them production costs.

The result is an increased risk of insolvency as companies struggle to pay the costs incurred.

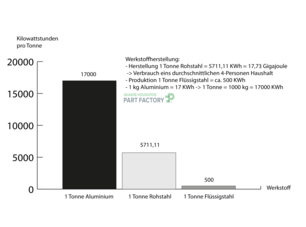

Due to the energy that contract manufacturers have to spend on production processes in order to manufacture the orders, production costs consequently increase. In addition, transportation costs and the production of materials are also becoming more expensive. Many companies are passing these rising costs on to their customers. The result is that they now have to bear the costs so that the company's profit margin is not negatively impacted. Furthermore, inflation has a big impact on rising prices, because inflation means companies have to raise prices to cover the emerging costs. This creates more costs for contract manufacturing companies and a big concern about the availability of gas in the coming months.

Companies that produce energy-intensive goods are affected by the increased prices and often feel the impact first.

It is precisely these companies that have to significantly curtail their operations.

Thus, given if productions have to be limited or stopped for good.

Consequently, companies are now asking themselves whether outsourcing to another European country could prove advantageous.

However, it must be mentioned at this point

that this energy crisis affects the whole of Europe.

So it would make less sense to outsource to other countries in the EU if they are struggling with the same problems.

In addition, suppliers and contract manufacturers often give a price premium for the long delivery routes and the associated delivery costs.

How will costs develop?

It is expected that costs may rise further in 2023 and 2024 if the existing situation continues to worsen.

Production prices for many product groups may increase, and customers would face higher prices as a result of rising production costs.

Furthermore, there may be price increases for various materials such as steel or plastics.

Future cost developments will depend on government measures and energy developments.

How can contract manufacturing costs be reduced?

Contract manufacturing customers can, in order to reduce the cost of the order,

obtain several offers and compare them with each other.

However, this would mean an additional expenditure of time for the customer.

He must make a comparison between the individual contract manufacturers in order not to run the risk of having to pay a much too high price for his order.

However, there are other ways to reduce costs.

In the box is a small summary of a few possibilities.

What solution does PART FACTORY offer?

PART FACTORY has a large network of qualified CNC subcontractors and compares the offers of the verified producers for your request, so that you get the most cost-effective offer. In this process, you do not have to ask anyone to find a subcontractor, because PART FACTORY will do it for you.

Furthermore, PART FACTORY provides you with a structured overview of the inquiries and orders received,

which you can access in the portal at any time.

A price comparison is even more worthwhile in the current time.

PART FACTORY helps you exactly at this point.

Thanks to our customer service and easy operation in the portal we help you to

to significantly reduce the time needed to obtain a quote.

Try our service!

Convince yourself of our uncomplicated service and make a production inquiry.

You will be surprised how little effort is required.

You can look forward to a high-quality prototype or a corresponding small series on the desired delivery date, which fully corresponds to your production drawing. Give it a try - it's worth it!

![[Translate to English:] PART FACTORY_Gas [Translate to English:] PART FACTORY_Gas](/fileadmin/_processed_/0/2/csm_PART_FACTORY_Gas_zu_bearbeitet_863802605f.png)

![[Translate to English:] PART FACTORY_Energiekrise [Translate to English:] PART FACTORY_Energiekrise](/fileadmin/_processed_/a/b/csm_PART_FACTORY_-_Energiekrise_-_bearbeitet_ea3e8a08a7.jpg)

![[Translate to English:] PART FACTORY_Energiekrise [Translate to English:] PART FACTORY_Energiekrise](/fileadmin/_processed_/d/4/csm_PART_FACTORY_Energiekrise_bearbeitet_2f92a70801.jpg)

![[Translate to English:] PART FACTORY - Kontaktaufnahme [Translate to English:] PART FACTORY - Kontaktaufnahme](/fileadmin/_processed_/2/4/csm_woman-2773007__340_590260e0fe.jpg)