The market for the manufacturing of metal turned and milled parts is growing steadily. This means that companies are increasingly outsourcing the manufacture of components from their own companies. Using procurement service providers is a convenient way to easily obtain the turned and milled parts they need. These procurement service providers draw on a large network of producers to fulfill their customers' requests. In this way, they are able to conveniently distribute an inquiry consisting of several components among any number of producers, so that the orders are processed in parallel and not one after the other. What are the advantages of placing the order and splitting it up if necessary?

Are there any reasons against it?

Advantages of splitting the production order in CNC contract manufacturing

Once the customer has set the request, the realization of the set components is the responsibility of the procurement service provider.

Here you receive free Tipps for the attitude of a manufacturing inquiry.

As soon as the procurement service provider has processed the request and created the selection of an offer, the order is placed.

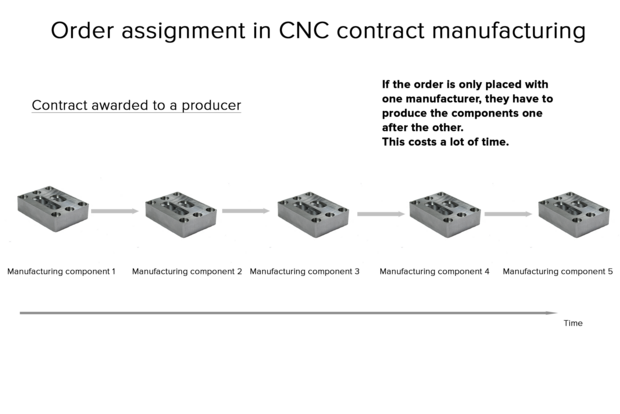

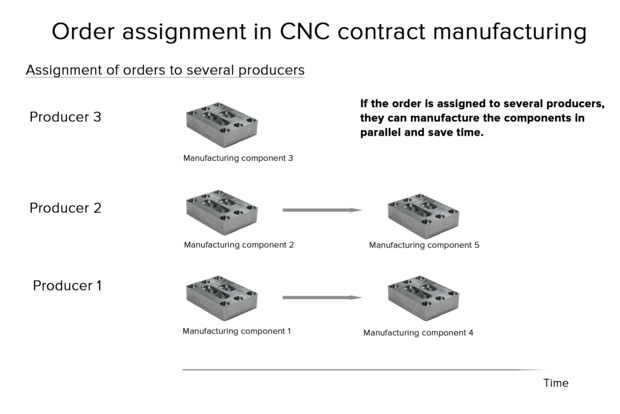

A significant advantage of dividing the order between many producers is the time factor. Since the individual producers can focus on the production of one component, they need less time. Therefore, if one producer handles several orders from one customer at the same time, the entire process is delayed (unless the manufacturing company has large free machine capacities). Finally, the individual components are produced one after the other and are only shipped to the customer once the entire production is completed. This can lead to a delay in the delivery date. However, if the customer's individual orders are distributed among several producers, they can manufacture the orders in parallel/simultaneously. The advantage of this is that the desired delivery date can be met, as the production of the individual orders takes place independently of each other. It is not necessary to first complete a production run in order to manufacture the next component and ship it to the customer.

Another advantage is that the production processes are independent of each other. If problems occur in production at one producer due to machine failure or delayed provision of the required material, the entire order is not affected. The realization of the ordered milled and turned parts can be continued without problems in the production of the producers who are not affected by the problem. Accordingly, the entire order is not slowed down, but only individual points delay the process. This has the advantage that the majority of the desired delivery dates can be met, since the entire production of all components does not have to be shut down.

Closely linked to this is the argument in favor of splitting the orders. If the orders are for components that are produced using different manufacturing processes, it is possible to benefit significantly from a large network of producers.

In case the requested producer is not able to manufacture the requested component, not all orders have to be rejected immediately. At PART FACTORY we give the requests only to the producers who are able to manufacture the components. In this way, the components that need to be turned can be manufactured by one of our producers, while a milled part can be manufactured by another producer that focuses on milling. Therefore, the requested components can be confidently placed in the hands of the producers who have the expertise and know-how to realize these components. This underlines once again the argument of independent manufacturing below the individual producers.

In addition, it should be mentioned that the division of orders can provide a price advantage. The producers give namely the price, which is market-fair for the orders. The customer profits from this by getting the most favorable partners for the particular turned and milled part. Since the producers look at the individual orders, they do not drive up the prices just because one of the components is more expensive to manufacture.

An obvious argument against this is the component quality. If the requested turned and milled parts are manufactured by different producers, they may in some cases differ in quality. This can lead to an inconsistent appearance or to limitations of the functions because the components are not matched to each other. Such errors can be avoided if you request components that absolutely must fit together because of the function to be performed as one assembly, or if the surface tolerances and specifications require a uniform appearance (e.g. anodizing). Here you can find out how to do this at PART FACTORY.

But also the surface finish can differ, because the producers, even using the same machine, can have different result.

This can happen due to things like the setting of the machine, the staff used and the possible post-processing (e.g. cleaning of the surface). In addition, complications can also arise during delivery. Since producers schedule production at their own pace and discretion, this can lead to variations in delivery. As mentioned above, problems may arise during production that force one of the producers to interrupt production. Consequently, the desired delivery date cannot be met. Accordingly, the delivery is incomplete and the entire process is delayed. However, factors such as inaccurate production planning can also lead to a delay in delivery. Here you can learn more about the advantages of contract manufacturing and how delays in production can be prevented.

Another argument against splitting the individual orders is the effort involved in making a complaint. If the deliveries do not meet the desired requirements or it is not manufactured according to the drawing, a complaint can be made. If the components were manufactured by different producers, the entire complaint process becomes complicated. Complaints must be submitted to several producers and, if necessary, a repair or new production must be discussed. If only part of the delivery is affected and a complaint has to be made, the rest of the requested components cannot be used if they urgently belong together.

PART FACTORY offers you a large network of tested and qualified producers. With us you have the opportunity to trustingly place your desired turned and milled parts in the hands of our producers. We at PART FACTORY try to minimize the disadvantages described above and to support you in the realization of your component. Here you can find out which other problems are eliminated by using the PART FACTORY B2B contract manufacturing portal.

We will pass on your request to the appropriate producer, so that you can benefit from the strengths of our manufacturers. You can request both individual parts and assemblies from us. Try it out for yourself and submit an inquiry quickly and easily.

Now that both sides have been discussed, the question arises as to whether it makes sense to split the orders or not. A division of the orders makes sense especially if it is not an assembly. If you need individual turned and milled parts, it makes sense to split these orders and benefit from our large network of qualified producers. We offer a variety of manufacturing processes so that nothing stands in the way of realizing your desired component.

Submit an inquiry today and benefit from the variety PART FACTORY has to offer you.

Test our service!

Convince yourself of our uncomplicated service and make a production enquiry.

You will be surprised how little effort is required.

You can look forward to a high-quality prototype or a corresponding small series on the desired delivery date, which fully corresponds to your production drawing. Give it a try - it's worth it!

![[Translate to English:] PART FACTORY - Kontaktaufnahme [Translate to English:] PART FACTORY - Kontaktaufnahme](/fileadmin/_processed_/2/4/csm_woman-2773007__340_590260e0fe.jpg)