The Ukraine war began on February 24, 2022 with the invasion of Ukraine by Russian troops. Before this event, the main talk was about Ukraine conflict.

With the beginning of the Ukraine war, the procurement of various raw materials and materials and import and export related to Russia and Ukraine became more difficult.

The European Union (EU) and the USA reacted to the behavior of Russia by imposing strict sanctions against Russia. For example, many EU and U.S. companies are responding to Russia by halting deliveries.

The effects of the Ukrainian war are already evident in the procurement of raw materials. Ores, metals and metal goods accounted for about ¼ of Ukrainian goods exports before the war, and the war destroyed a large steel plant in Mariupol.

This ensures that steel goods from Ukraine are throttled.

But how big are Ukraine's production and raw material shares?

Ukrainian companies Cryoin and Ingas account for up to 50% of neon production worldwide, and the production losses have a major impact on economic sectors.

The raw material share of pig iron from Ukraine in the world production in 2020 was 2%.

Of iron ore, the share from Ukraine in world production in 2020 was 3% and of titanium 2%.

In addition to Ukraine, a significant share of production and raw materials is located in Russia.

The production share of Russia in the world market share of palladium is more than 40%, of titanium - 13%, and of nickel - about 10%.

Russia's raw material share in world production in 2020 was 4% for pig iron and crude steel, and 9% for sawn timber. For platinum, the raw material share was 14%, for industrial wood 11% and for aluminum 6%. (Source: GTAI and economiesuisse Federation of Swiss Businesses).

The war leads to a shortage of individual products,

the shortage, in turn, leads to an increase in prices because the supply is lower. In addition, securities trading companies expect

due to the resulting shortage of aluminum supplies, expect aluminum prices to rise. Within twelve months, prices can reach 4000 US§ (source: FUTURA), which may also apply to several commodities in the future.

Furthermore, the war has an impact on our energy, because Russia is one of Germany's energy suppliers. For example, about half of Germany's imported hard coal and natural gas comes from Russia (source: ifo Schnelldienst digital). This creates a lot of concern and uncertainty about a gas supply freeze and future prices.

In 2021, imports from Ukraine to Germany amounted to 414 million euros and imported metals and metal products from Russia were worth 4.6 billion euros

(Source: ifo Schnelldienst digital).

With the start of the Ukraine war, the price shock followed.

The number of imports rose sharply, so that the number of imports in March 2022 was 69% higher than the previous month's value. As a possible explanation, early imports can be considered, which provides raw material coverage for companies before upcoming sanctions. In March 2022, exports to Russia then, plummeted by more than half.

Imports and exports also face problems in the logistics industry, as rising fuel prices and a shortage of drivers complicate the process. The problem of driver shortage mainly refers to the 100,000 missing Ukrainian drivers.

The Ukraine war is also causing import and export costs from other countries to rise.

As a result, the cost of transporting a container from Shanghai to Rotterdam has risen sharply.

Shortly after the war began, the cost briefly rose from less than US$2,000 in 2020 to US$54,000.

Furthermore, companies from various sectors of the economy are withdrawing from Russia. They are sharply reducing exports, imports and production in Russia. In the logistics sector, several logistics companies suspended shipments to Russia and Ukraine after the war began. For example, no more shipments were sent to Russia and transport services to and from Ukraine were stopped.

(Source: tagesschau / Norddeutscher Rundfunk)

Many more companies, also in various sectors of the economy, such as telecommunications

the financial sector, electronics or the automotive industry are reacting to the Russian-Ukrainian war by withdrawing or curtailing operations in Russia.

Reaction of the European Union and Russia with sanctions:

To respond to the war starting from Russia, the European Union (EU) expanded the 2014 sanctions against Russia.

Thus, the EU member states adopted eight sanctions packages against Russia

(Source: the German government / Press and Information Office of the German government) (as of Dec. 19, 2022).

These include, for example, import restrictions on precious metals, stones and plastics or other import bans from Russia.

But Russia defends itself against the sanctions of the EU and reacts with various entry bans or export bans as counter-sanctions

(Source: Chamber of Commerce Abroad).

The shortage of raw materials and the various problems with the import and export of goods, also have an impact on the production and availability of tools.

Raw materials that are needed for the production of tools such as a steel hammer and come from the affected countries will be more difficult and expensive to obtain due to the war. As a result, the tools cannot be manufactured without the required raw material or there will be delays in production. For tools that are produced directly in Russia or Ukraine and exported to other countries, the war creates the same problem, of increased cost and availability. In addition, the export and import can even be completely prevented by further sanctions.

The above-mentioned raw material, import and export problems,

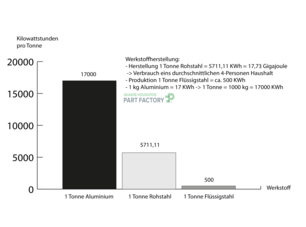

caused by the war in Ukraine are having a negative impact on contract manufacturing and are causing (price) problems and bottlenecks for contract manufacturers. Rising prices for raw materials make it difficult for contract manufacturers to obtain affordable raw materials. In addition, rising energy prices are making contract manufacturers' production processes more expensive, especially because energy requirements in metal production are covered by coal or natural gas, and one of the most important suppliers of hard coal and natural gas to Germany is Russia.

Raw material and energy prices make the prices of the final product increase. Customers have to bear this price increase caused by the war. Furthermore, contract manufacturing is affected by the difficulties in import and export. This is because the shortage of drivers and the rise in fuel prices are being felt by delivery services in Germany, which are also having to adjust their prices.

The shortage of materials and tools also leads to longer delivery times of the product to the client.

Many companies are already suffering from bottlenecks and are uncertain about the development of production.

Thus, 18% of the companies expect that they will have to limit their production and 38% of the companies expect missing deliveries, which they will find difficult or impossible to replace. (Source: ME GESAMTMETALL)

In addition, many raw materials were already scarce and expensive before the war; with the start of the war, this situation has worsened and prices have risen massively.

In case of further aggravation of the war or further sanctions, there will also be further cost increases and deepening difficulties on contract manufacturing.

Because the Ukraine war is also having an impact on other countries - especially the energy crisis, which is being fueled by the sanctions - many companies in Europe are being affected by the consequences.

In summary, the Ukraine war is having an impact on various but important areas of contract manufacturing. Among other things, the transport of goods to and from Russia and Ukraine is severely restricted. Important raw materials such as steel and energy sources, mainly gas, are affected by shortages,

causing world market prices to rise dramatically. Supply chains related to Russia and Ukraine have also been destroyed in the short term and must first be (expensively) rebuilt.

This all has a direct impact on contract manufacturing.

Contract manufacturers have to buy raw materials and energy more expensively and may even be affected by delivery delays, delaying the start of component production.

The rising prices and delivery delays then extend to the customer, who must then bear them.

Furthermore, the sanctions of the European Union and the counter-sanctions of Russia make the daily work of the contract manufacturers even more difficult, as the extent of future sanctions cannot be foreseen for the time being. It is also to be expected that further consequences will be imposed and that contract manufacturing will have to adapt again if the situation deteriorates further.

PART FACTORY builds on a network of verified producers.

Due to the large number of producers, prices can be compared easily and quickly and free capacities can be used more easily, for example to shorten delivery times. Furthermore, due to this high number, a diverse selection of materials and a variety of manufacturing processes to be selected are possible.

Further advantages of PART FACTORY can be found in the box:

Try our service!

Convince yourself of our uncomplicated service and make a production inquiry.

You will be surprised how little effort is required.

You can look forward to a high-quality prototype or a corresponding small series on the desired delivery date, which fully corresponds to your production drawing. Give it a try - it's worth it!

![[Translate to English:] PART FACTORY_russisch-ukrainischer Krieg [Translate to English:] PART FACTORY_russisch-ukrainischer Krieg](/fileadmin/_processed_/d/5/csm_PART_FACTORY_russisch-ukrainischer_Krieg_1ff6300acb.jpg)

![[Translate to English:] PART FACTORY_Prozent [Translate to English:] PART FACTORY_Prozent](/fileadmin/_processed_/d/2/csm_PART_FACTORY_Prozent_bearbeitet_45aa50ed58.png)

![[Translate to English:] PART FACTORY_Währung [Translate to English:] PART FACTORY_Währung](/fileadmin/_processed_/b/3/csm_PART_FACTORY_Waehrung_schwarz_daf7e2360c.png)

![[Translate to English:] PART FACTORY_Container [Translate to English:] PART FACTORY_Container](/fileadmin/_processed_/a/0/csm_PART_FACTORY_Container_0eb692e27a.jpg)

![[Translate to English:] PART FACTORY_Import und Export [Translate to English:] PART FACTORY_Import und Export](/fileadmin/_processed_/d/d/csm_PART_FACTORY_Import_Export_Fragen_bearbeitet_b4cdbc5b27.png)

![[Translate to English:] PART FACTORY_weltweite Preissteigerung [Translate to English:] PART FACTORY_weltweite Preissteigerung](/fileadmin/_processed_/4/a/csm_PART_FACTORY_weltweite_Preissteigerung_bearbeitet_ee1c2df520.png)

![[Translate to English:] PART FACTORY_Liste [Translate to English:] PART FACTORY_Liste](/fileadmin/_processed_/e/0/csm_PART_FACTORY_Liste_bearbeitet_cf3d03375b.png)

![[Translate to English:] PART FACTORY_Sanduhr [Translate to English:] PART FACTORY_Sanduhr](/fileadmin/_processed_/0/8/csm_PART_FACTORY_Sanduhr_transpartent_9e9dbc2555.jpg)

![[Translate to English:] PART FACTORY - Kontaktaufnahme [Translate to English:] PART FACTORY - Kontaktaufnahme](/fileadmin/_processed_/2/4/csm_woman-2773007__340_590260e0fe.jpg)